Logistics trolleys play a vital role in the future of logistics and modern supply chains. They enhance efficiency and streamline operations across various industries. The surge in e-commerce has heightened the demand for effective material handling solutions. Additionally, environmental policies now push industries toward low-emission equipment, like electric forklifts. The COVID-19 pandemic has underscored the necessity for quick adaptability in supply chains, driving the need for innovative logistics trolleys as we look toward the future of logistics.

Key Takeaways

- Logistics trolleys enhance efficiency in supply chains, especially with the rise of e-commerce.

- Ergonomic designs in trolleys reduce physical strain, improving worker comfort and safety.

- Automated trolley systems increase speed and safety, minimizing manual labor and injury risks.

- Sustainability is a priority, with manufacturers using eco-friendly materials to reduce environmental impact.

- Customization and modularity in trolley designs meet the specific needs of various industries.

- Integrating IoT and AR technologies improves tracking, navigation, and decision-making in logistics.

- Healthier workers using ergonomic trolleys are more productive, leading to better operational performance.

- The future of logistics trolleys will focus on automation, sustainability, and advanced technology integration.

Ergonomics in Logistics Trolleys

Design Innovations

Modern logistics trolleys have undergone significant design innovations aimed at enhancing ergonomics. These advancements prioritize user comfort and operational efficiency. Key innovations include:

- Lightweight Materials: Manufacturers now utilize advanced composites and high-strength alloys. These materials improve durability while making trolleys easier to maneuver.

- Swivel Casters: The incorporation of swivel casters reduces push forces, minimizing physical strain on workers. This feature allows for smoother navigation in tight spaces.

- Modular Designs: Customizable trolley designs cater to various work environments. This adaptability promotes safety and efficiency, allowing businesses to tailor equipment to their specific needs.

A table summarizing common ergonomic features found in modern logistics trolleys highlights their importance:

| Ergonomic Feature | Description |

|---|---|

| Automatic brakes | Enhance safety by improving handling on stairs or slopes. |

| Non-slip grips | Reduce operator fatigue, providing better control during use. |

| Adjustable handles | Allow for customization to suit different user heights and preferences. |

| Shock-absorbing wheels | Ensure smooth movement over uneven surfaces, enhancing user comfort. |

Health Benefits

The health benefits of ergonomically designed logistics trolleys are substantial. These improvements significantly enhance worker comfort and reduce injury risks. For instance, height-adjustable workstations and lifting aids minimize the need for manual lifting, which can lead to strains and back pain. Healthier workers tend to be more productive, as they can focus on their tasks without the strain of poorly designed equipment. This leads to fewer errors and faster turnaround times, ultimately improving operational performance.

Moreover, the following health benefits have been documented from using ergonomically designed logistics trolleys:

- Reduced risk of injuries: Ergonomically designed trolleys minimize the need for manual lifting, which can lead to strains and back pain.

- Enhanced safety: Features like adjustable handles and smooth-rolling wheels contribute to safer handling of goods.

- Improved productivity: By facilitating easier transportation of items, employees can focus on their core tasks, indirectly supporting their physical well-being.

Automation and Robotics

Automation and robotics are transforming the landscape of material handling, particularly in logistics trolleys. These advancements enhance efficiency, safety, and productivity across various industries.

Automated Trolley Systems

Automated trolley systems represent a significant leap forward in logistics operations. These systems utilize electric motors and advanced technology to streamline the movement of goods. The advantages of automated trolleys compared to manual alternatives are substantial:

| Advantage | Automated Trolleys | Manual Trolleys |

|---|---|---|

| Efficiency | Faster movement of goods | Slower due to manual effort |

| Safety | Reduced risk of injury | Higher risk due to physical strain |

| Load Capacity | Can handle heavier loads | Limited by manual strength |

| Physical Strain | Minimizes fatigue and strain | High physical effort required |

| Versatility in Terrain | Performs well on various surfaces | Limited to flat surfaces |

The integration of automated trolley systems leads to increased efficiency due to electric motors enabling faster movement. Operators experience reduced physical strain, which lowers the risk of injuries. These systems can handle heavier items safely, enhancing overall safety with features like automatic speed control. Furthermore, automated trolleys navigate various terrains effectively, making them versatile for different operational environments.

Robotics in Material Handling

Robotics plays a crucial role in optimizing material handling operations. Automated robots enhance efficiency by performing tasks faster and more accurately than human workers. They excel in repetitive tasks, maintaining high precision and speed beyond human capability. Key benefits of robotics in material handling include:

- Robots optimize workflows and reduce downtime.

- They work continuously without breaks, ensuring a non-stop production cycle.

- Automated robots efficiently retrieve items from high shelves and navigate large warehouses, reducing order-to-shipment time.

- Equipped with sensors, robots can detect obstacles, minimizing workplace accidents.

The integration of robotics into logistics trolley systems can lead to a significant reduction in logistics costs by as much as 40%. Additionally, productivity can increase between 25% and 70%. These improvements stem from automating routine tasks, which minimizes errors and optimizes supply chain management. As industries continue to embrace these technologies, the future of logistics will undoubtedly rely on the seamless integration of automation and robotics.

Sustainability Trends

Sustainability has become a critical focus in the logistics industry. As environmental concerns grow, manufacturers are increasingly adopting eco-friendly practices in the production of logistics trolleys. This shift not only meets regulatory requirements but also aligns with consumer expectations for sustainable products.

Eco-Friendly Materials

The use of eco-friendly materials in logistics trolley production is on the rise. Manufacturers are prioritizing sustainable options to reduce their environmental impact. Key materials include:

- Recycled Plastic: TTS trolleys incorporate a significant number of components made from recycled plastic, certified by the Plastic Second Life (PSV) standard. Similarly, the EU Ecolabel-certified Magic trolleys contain at least 30% recycled plastic, ensuring a lower environmental footprint.

- Recycled Metal: The shift towards sustainable materials also includes the use of recycled metal, which serves as an eco-friendly alternative to traditional materials.

- Eco-Friendly Coatings: Manufacturers are exploring alternatives like eco-friendly coatings and components to enhance sustainability further.

These materials not only contribute to a reduced carbon footprint but also promote a circular economy by minimizing waste.

Energy Efficiency

Energy-efficient logistics trolleys play a vital role in enhancing overall warehouse sustainability. Their design and functionality contribute significantly to reducing energy consumption and waste. The following table outlines how energy-efficient trolleys contribute to sustainability:

| Contribution to Sustainability | Description |

|---|---|

| Reduction of Disposable Packaging | Energy-efficient trolleys minimize the need for single-use plastics and cardboard, leading to less waste. |

| Enhanced Durability | Their robust construction ensures a longer lifespan, reducing the need for replacements and associated waste. |

| Promoting Recyclability | Made primarily of metals like steel, these trolleys can be recycled, saving energy and reducing emissions. |

| Improved Energy Efficiency | Efficient loading reduces vehicle idling and maximizes load capacity, leading to lower fuel consumption and emissions. |

Recent advancements in energy efficiency have further improved the performance of logistics trolleys. The following table highlights some of these innovations:

| Feature | Description |

|---|---|

| Regenerative braking systems | These systems capture energy during braking, enhancing overall energy efficiency. |

| Smart power management | This feature optimizes energy usage, further improving the efficiency of operations. |

| Elimination of local emissions | The electric operation of trolleys reduces carbon footprints and noise pollution significantly. |

By integrating these energy-efficient features, logistics trolleys not only support the future of logistics but also contribute to a more sustainable supply chain.

Customization and Modularity

Customization and modularity in logistics trolleys have become essential for meeting the diverse needs of various industries. As businesses strive for efficiency, tailored solutions offer significant advantages in material handling.

Tailored Solutions for Industries

Different sectors increasingly adopt customized logistics trolleys to enhance operational efficiency. Industries such as automotive, electronics, aerospace, healthcare, and industrial manufacturing are at the forefront of this trend. These sectors require specific trolley designs to accommodate unique workflows and product types. For instance, in the healthcare sector, tailored trolleys facilitate emergency response and medical transport, ensuring quick access to essential supplies.

Industries utilizing customized logistics trolleys include:

- Automotive

- Electronics

- Aerospace

- Healthcare

- Industrial Manufacturing

The demand for tailored solutions reflects the need for efficiency in material handling. Customized trolleys can significantly improve workflow, reduce downtime, and enhance safety in various applications.

Modular Designs

Modular designs in logistics trolleys offer flexibility and adaptability, allowing businesses to modify their equipment according to changing needs. These designs enable companies to optimize their material handling processes effectively. The following table outlines the key benefits of modular trolley designs:

| Benefit | Description |

|---|---|

| Enhanced Mobility | Trolleys allow for easy transport of heavy loads, reducing physical strain and increasing operational speed. |

| Optimized Storage Solutions | Modular designs enable customization for various operational needs, maximizing storage efficiency. |

| Improved Workflow and Ergonomics | Trolleys bring materials closer to operators, reducing the risk of injuries and improving efficiency. |

| Integration with Lean Manufacturing | Trolleys can be incorporated into automated systems, supporting modern manufacturing principles. |

| Time and Cost Savings | Efficient material handling reduces wasted motion, leading to significant cost savings over time. |

The modular approach allows for adjustable shelving and user-friendly designs, making it easier to adapt to different load sizes and shapes. Features such as custom steering configurations enhance maneuverability, while the ability to tow trolleys with electric tuggers or automated guided vehicles (AGVs) improves transportation efficiency.

Technology Integration

The integration of technology into logistics trolleys is revolutionizing material handling processes. Two significant advancements in this area are the Internet of Things (IoT) and Augmented Reality (AR). These technologies enhance efficiency, safety, and decision-making in logistics operations.

IoT in Material Handling

The Internet of Things (IoT) plays a crucial role in modernizing logistics trolleys. By implementing an Industrial Internet of Things (IIoT) and Digital Twin (DT) platform, companies can significantly enhance the traceability and visibility of their logistics operations. This approach treats each location as a ‘trolley’ in the digital realm, standardizing tracking processes and improving information management. As a result, businesses can facilitate more efficient logistics operations.

The measurable benefits of IoT-enabled material handling equipment include:

- Continuous monitoring of operational hours and fuel consumption ensures optimal use and extends asset life.

- Real-time sensor data detects equipment wear, enabling targeted interventions before failures occur.

- Automated records and blockchain systems reduce audit risks and compliance time by 40%.

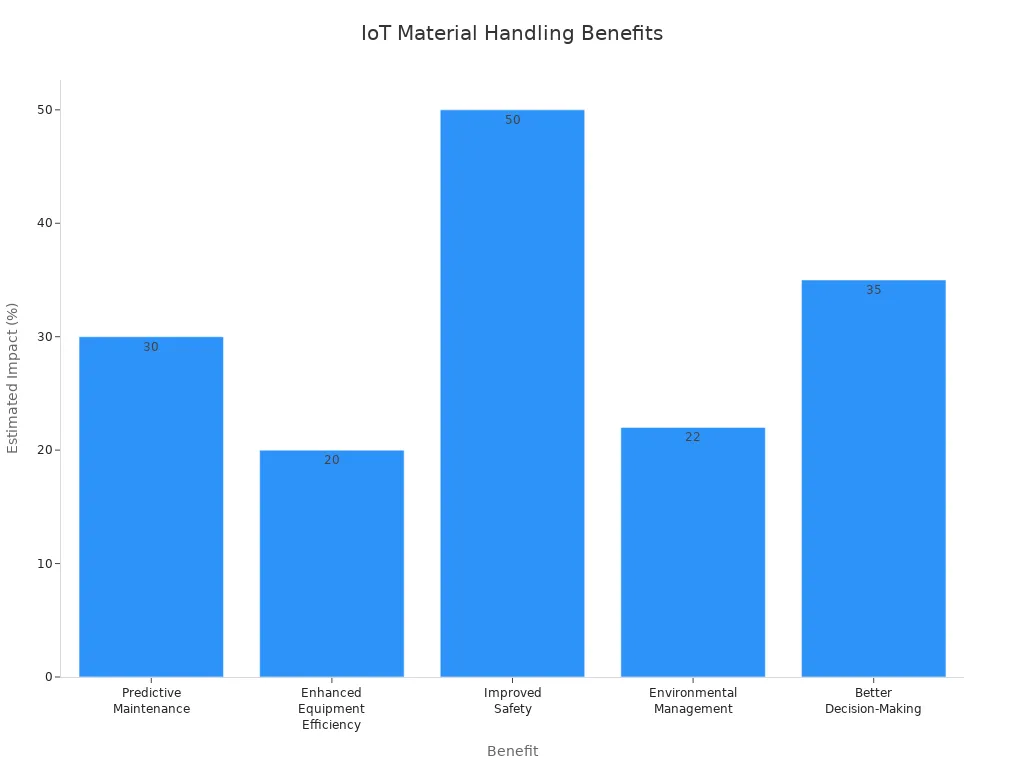

| Benefit | Description | Estimated Impact |

|---|---|---|

| Predictive Maintenance | Sensors monitor equipment performance, allowing maintenance only when needed. | Reduces unplanned downtime by up to 30% |

| Enhanced Equipment Efficiency | Real-time data collection optimizes equipment use and reduces waste. | Increases utilization by 15-20% |

| Improved Safety | Instant alerts for hazardous conditions prevent accidents. | Reduces safety incidents by up to 50% |

| Environmental Management | Monitoring emissions supports compliance with environmental standards. | Reduces emissions by up to 22% |

| Better Decision-Making | Centralized dashboards provide actionable insights for rapid response. | Improves decision speed by 35% |

These advancements not only streamline operations but also enhance overall productivity and safety in logistics environments.

Augmented Reality (AR)

Augmented Reality (AR) is another transformative technology in logistics trolley operations. AR enhances training and operational efficiency by providing visual instructions and interactive experiences for workers. This technology significantly improves navigation in warehouses, helping employees locate items quickly and accurately.

Key applications of AR in logistics include:

- AR enhances training programs by making them interactive and effective.

- It optimizes order picking processes by visually guiding workers, leading to improved efficiency and customer satisfaction.

- Companies like XPO Logistics use AR to display diagrams that assist workers in accurately collecting goods.

- DHL has implemented AR systems in its warehouses, resulting in increased efficiency and fewer errors.

By integrating AR into logistics operations, companies can reduce errors and speed up processes, ultimately enhancing customer satisfaction. The combination of IoT and AR technologies positions logistics trolleys at the forefront of innovation in material handling, paving the way for a more efficient and responsive supply chain.

Industry-Specific Applications

E-commerce and Retail

Logistics trolleys play a crucial role in enhancing efficiency within e-commerce and retail fulfillment operations. They streamline the picking process and reduce travel time for workers, which is essential in fast-paced environments. Here are some key benefits of using logistics trolleys in this sector:

- They help maintain organization in busy environments.

- Improved order accuracy leads to higher customer satisfaction.

- Shaving just 10 seconds off the time it takes to locate, pick, and deliver SKUs can significantly increase capacity, reduce costs, and boost employee morale.

The e-commerce and retail sectors often face unique challenges, such as a high concentration of SKUs and frequent orders. The following factors highlight the specific requirements for logistics trolleys in these industries:

- High concentration of SKUs stored.

- Small and easy-to-manually pick SKUs.

- Frequent orders with common SKUs.

- Limited amount of unique SKUs.

To meet these demands, logistics trolleys often feature:

| Feature | Description |

|---|---|

| Multi-level shelves | Organize products by order for efficient picking. |

| Ergonomic handles | Reduce strain on workers during long shifts. |

| Integrated technology | Supports real-time inventory updates to minimize errors. |

| Custom labeling | Helps workers quickly identify products and prevent mix-ups. |

| Adjustable dividers | Allows for flexible organization based on inventory needs. |

These features enhance the overall efficiency of material handling in e-commerce and retail, ensuring that businesses can meet customer demands effectively.

Healthcare Sector

In the healthcare sector, logistics trolleys serve a vital function in material handling. They improve efficiency by providing enhanced organization and accessibility of medical supplies. Their versatility allows for use in various hospital settings, which is crucial during emergencies. Key requirements for logistics trolleys in healthcare include:

- Safety features such as lockable drawers and anti-tip stability.

- Easy-to-clean surfaces to maintain hygiene.

- Durable materials resistant to disinfection processes.

Additionally, ergonomic considerations are paramount. Trolleys should have:

- Height suitable for average users to prevent excessive bending.

- Ergonomically designed handles to reduce strain.

- Smooth-rolling casters for easy maneuverability.

Durable materials like stainless steel and high-strength plastics ensure longevity while lightweight options facilitate easier maneuvering. The size of the trolley should accommodate different healthcare needs, and mobility features must enable navigation through tight spaces efficiently.

Logistics trolleys in healthcare settings enhance operational effectiveness. Features like lockable compartments and customizable storage options ensure that essential items are secure and easily retrievable. This organization streamlines hospital operations, allowing healthcare professionals to focus on patient care rather than searching for supplies.

The logistics trolley industry is witnessing several key trends that shape its future. These include:

- Increased demand driven by e-commerce

- Emphasis on workplace ergonomics and safety

- Adoption of lean manufacturing principles

- Focus on sustainability

- Growing interest in customization options

- Technological advancements in trolley design

Innovation plays a crucial role in maintaining competitiveness in supply chain operations. As industries evolve, they require efficient material handling solutions. Innovations such as AI-driven trolleys enhance real-time visibility and improve inventory turnover by 15-30%.

Looking ahead, the future of logistics will likely feature fully automated, AI-driven trolleys that integrate with drones and robotic systems. Sustainability will remain a priority, with biodegradable materials and carbon-neutral processes becoming standard.

FAQ

What are logistics trolleys?

Logistics trolleys are mobile equipment designed for transporting goods within warehouses, retail spaces, and manufacturing facilities. They enhance efficiency by streamlining material handling processes.

How do ergonomics improve logistics trolleys?

Ergonomics enhance logistics trolleys by incorporating user-friendly designs. Features like adjustable handles and lightweight materials reduce physical strain, promoting worker safety and comfort.

What role does automation play in logistics trolleys?

Automation increases efficiency in logistics trolleys by enabling faster movement of goods. Automated systems minimize manual labor, reduce errors, and enhance overall productivity.

Why is sustainability important in logistics trolleys?

Sustainability is crucial as it reduces environmental impact. Manufacturers focus on eco-friendly materials and energy-efficient designs to meet regulatory standards and consumer expectations.

How can logistics trolleys be customized?

Logistics trolleys can be customized to meet specific industry needs. Tailored designs accommodate unique workflows, enhancing operational efficiency in sectors like healthcare and automotive.

What technologies are integrated into modern logistics trolleys?

Modern logistics trolleys integrate technologies such as IoT for real-time tracking and AR for improved navigation. These advancements enhance efficiency and decision-making in material handling.

How do logistics trolleys benefit the healthcare sector?

In healthcare, logistics trolleys improve organization and accessibility of medical supplies. They enhance operational efficiency, ensuring quick access to essential items during emergencies.

What trends are shaping the future of logistics trolleys?

Key trends include increased automation, a focus on sustainability, customization options, and the integration of advanced technologies. These trends drive innovation in material handling equipment.